Country Reiten: Paddock mats without substructure – Bacher Products ArenaMat. Test passed!

As part of our major comparative test of paddock mats, which should be able to be laid without a substructure, we also took a closer look at the ArenaMat from Bacher Products and tested it over all seasons. Can this model, which functions quite differently from the other test participants, actually pass the test?

The mats from Bacher Products have been in the Country-Reiten.de test area for almost a year now. It had to withstand heat and torrential rain, prove itself in muddy and rainy autumn weather and at sub-zero temperatures in winter. We drove over it with the tractor, made steering movements on the spot and took horses with and without shoeing.

Since the mats are simply laid on the subsoil (Bacher Products only recommends spreading a layer of sand or gravel approx. 5 – 7 cm thick to level it out underneath) and do not form a bond with each other, we were very curious to see whether this would prove its worth in tough everyday use. It can already be said that the ArenaMat has passed the test with flying colours and, in the overall view, should certainly be among the test winners and purchase recommendations.

A few facts

The ArenaMat is sustainably manufactured from surplus imitation leather that comes from the automobile industry. The design with the nubbed structure should not only allow water to flow off easily, but also to be stored for longer, which in turn should reduce dust formation.

Measuring 1.25 x 0.8 m, an ArenaMat is exactly one square meter in size, 4 cm high and weighs 19 kilos. The above-mentioned nubbed structure ensures sufficient grip in the substrate.

The material appears very soft in warmer temperatures, which is great for covering slight curves and transitions, e.g. to slopes. In winter, the material is less elastic, but can still be laid well.

Installation according to regulations and otherwise

As with all products we test, we follow the manufacturer’s recommendations. For this reason, we have provided a test area with a levelling layer of approx. 5 cm of sand, laid the ArenaMats on top of it and then filled it with sand. Since we are curious, we selected another test area in autumn, which already had about 5 – 10 cm deep mud. Without sand underlay, we simply laid the mats there and also did not fill them with sand, but spread mud directly on them. In addition, every time it rained, it dripped from a defective gutter onto a section of the roof.

The actual laying – whether directly on sand or in the mud – is very easy because the mats are simply laid on the ground. Edge to edge with an expansion joint of about 1 to 2 cm. Afterwards the backfilling takes place. Whether one fills the plates only up to the upper edge or a little above it, one can argue about that. The more sand is used as a treading layer, the more cushioning and water retention is naturally achieved. Also the mats have less abrasion and there are no problems with slipping horses.

But, conversely, more sand unfortunately also means all the more opportunities for an unhealthy bacterial world to develop from urine, horse excrement and hay residues. We ourselves therefore only use a thin layer of sand and let horses walk on the surface. Here the ArenaMats score with their structure, which offers hooves a lot of grip.

In our experience, an edge mounting for the ArenaMats does not seem necessary, because the panels lie very firmly on the ground due to their own weight and the nubby surface. Even steering with the tractor on the spot or horses spinning on their hooves are not impressed by the ArenaMat in any way.

It is optimal if the surface to be paved is built with a slight slope so that water can run off directly at the surface in the desired direction and does not have to seep completely through plates and filling into the ground.

Are they good or are they good?

The question of all questions can be answered with a clear yes. The ArenaMat was absolutely convincing in many aspects. It is easy to install and lasts throughout the year, very good. Even abrasion or wear, as other mats sometimes show after a shorter test time, could not be detected. Even the unprotected edges, which have direct contact with hooves, showed no signs of breakage or wear.

This is not only true for the “correctly” installed ArenaMats, but also the mats installed under tough conditions have been completely convincing. Despite the lack of interlocking and connection, the mats remain securely in place. They can be easily removed and reused – an advantage of the non-toothing design. This is an important point from a value retention perspective. It may not be advisable to lay it in knee-deep mud, where interlocking can provide the decisive one percent more grip through a closed bond, but it is amazing how well the ArenaMat has proven itself.

The only thing we could not observe were the special water-draining and water-storing properties, because boards from other manufacturers, which are laid in the same places, showed similar behaviour here after rainfall or in the formation of dust.

Conclusion

The ArenaMat has inspired us all around. It is an easy to install solution that reliably fixes surfaces in the equestrian area without a substructure. Even constant stress from horses and machines does not bother her. If you look at the price of 14.04 euros gross per square metre (for a purchase of 100 square metres), there are hardly any alternatives on the market that are so durable and so little slippery on the one hand, can be reused and require no substructure. Thus, the ArenaMat is currently the cheapest, reusable mat in our test.

In the concluding article of our comparison test, the ArenaMat should definitely be scratching the top spot.

Intermediate result

Country Reiten paddock mats without substructure – Bacher Products ArenaMat. Something completely different!

With the ArenaMat from Bacher Products, we have included a paddock mat in our major comparison test with ten different paddock mats to date. The ArenaMat differs from all other candidates in its construction, because the ArenaMat does not require any connections. We were curious to see if this could work at all. And – this much we can say – the ArenaMat really surprised us…

Since all five new models in our test have only been in use for about six months, we cannot yet make a final conclusion about their qualities at this point. But initial tendencies can already be seen after half of the test period.

A few facts

If you see the ArenaMat for the first time, you will notice its size and weight. According to Bacher Prodcuts, they are made of a sustainable – recycled plastic material – the environmental compatibility of which has been proven by independent authorities.

Bacher Products praises the optimal water properties of the panels. Due to the construction, on the one hand the moisture in the treading layer should be kept constant to keep dust formation as minimal as possible and on the other hand the construction should provide good drainage so that water can get into the subsoil.

At 1.25 x 0.8 m, the ArenaMat measures exactly one square metre and weighs around 19 kilos each. The structure of the 4 cm high panels is intended to provide the necessary support in the subsoil.

The entire construction appears relatively soft – especially in summer temperatures – and appears almost elastic. This means that, to a certain extent, they adapt well to the subsoil. This is perfect, for example, for places where the fastening must be laid over slope edges, as the slabs follow the course of the ground surface well here.

The slabs are simply laid on the ground, preferably on a layer of sand or gravel, so that they have a good grip and water can drain off easily. They have no connection between each other. Due to their special construction with studs, their own weight and the filling with sand, they should nevertheless remain sufficiently secure in their place.

For an endurance test we have additionally placed a test area directly in the light mud – without any sand or gravel – to see what happens to the slabs there.

On the floor

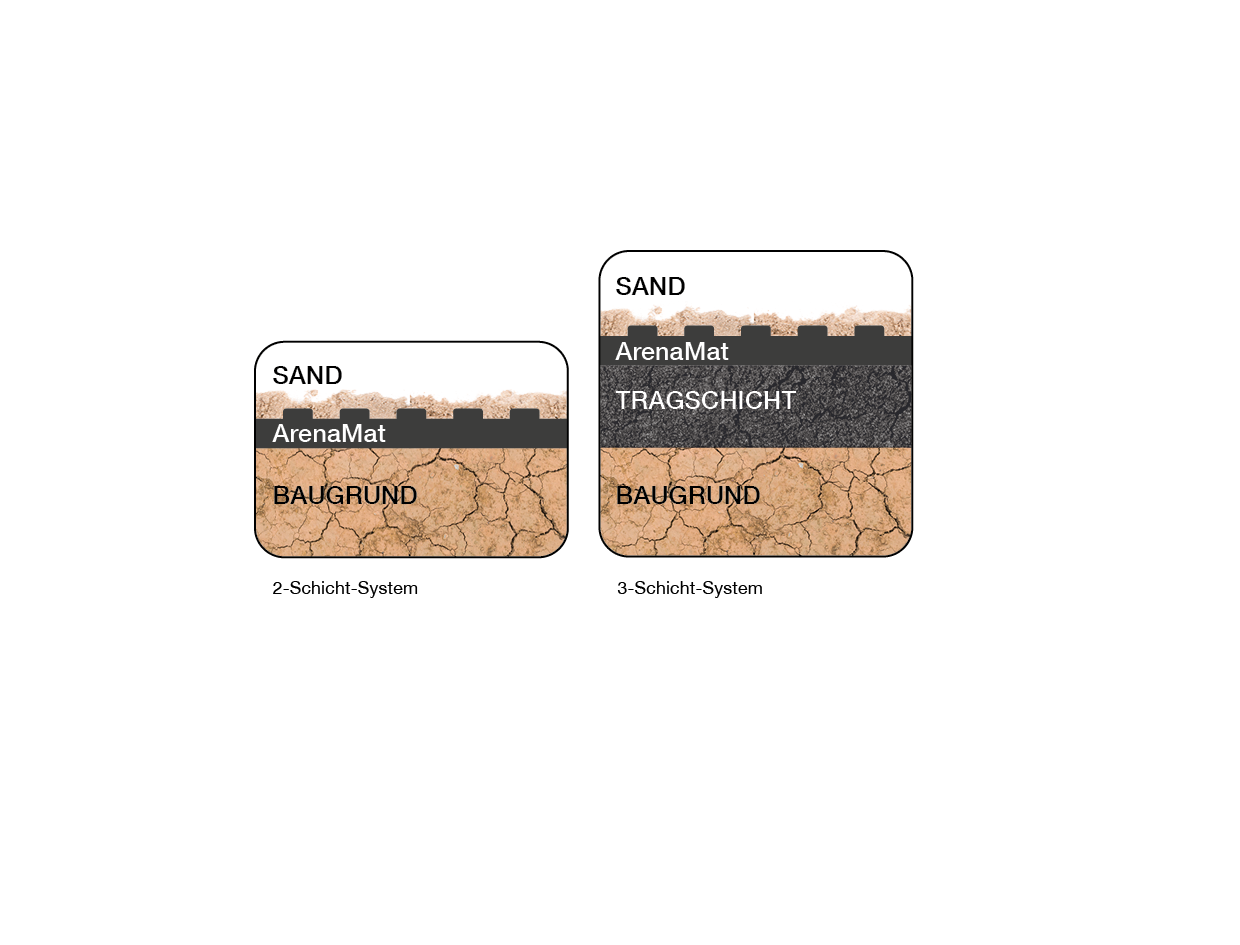

For a perfect result, the manufacturer recommends laying the slabs directly without a substructure in the case of load-bearing and sandy soils, or applying a layer of sand or gravel approx. 5 to 7 cm high in the case of a grown soil which should be sufficiently load-bearing and straightened. If the soil is not sufficiently load-bearing, a substructure is required.

It is advisable to allow for a slight gradient so that water accumulation does not occur. The slabs are simply laid edge to edge to the next slab without interlocking. It is best to leave a gap of 1 to 2 cm between the panels as an expansion joint. All in all, laying the panels is extremely quick and easy.

As soon as all the tiles are in the desired position, you should fill them with sand at least up to the top of the nubs. If you want to build a tread layer, apply more sand to the slabs. However, as the panels with their studded structure are pleasantly slip-resistant, it is absolutely sufficient here to fill with sand only up to the upper edge of the studs. The elasticity of the panels also provides a certain amount of self-insulation – but of course this would not replace a complete layer of sand.

Price and first impression

We were particularly curious about the ArenaMat and how it would perform, because its design makes it stand out from the rest of the test environment. So far, we’ve been more than pleasantly surprised by this solution, because the panels actually stay bomb-proof in place. No matter whether horses make turning movements on them, you steer the tractor onto them while standing still or put other loads on them, they hold together very well and securely. No corner or edge has shifted up or down, which was quite a fear in advance due to the missing interlocking. The test surface, which was laid directly on the ground, also withstands all loads impressively well.

But perhaps the long experience of Bacher Products is also evident here, since the ArenaMat was also used by the HIT company for their active stables until recently.

Thanks to the knobs, slipping is not an issue at all, and yet it can be used to remove paved surfaces easily. The only thing we couldn’t really determine was the drainage and anti-dust effect. Dust formation in summer was – at least from a visual point of view – just as high as with the other test models, which are installed directly next to the ArenaMat. And the water doesn’t seep away much faster with the panels than with the other test participants. But – to make it clear once again – the panels have been doing their job so far and very well.

Due to the lack of interlocking, the panels can simply be removed and reused. In really deep mud, however, the plates should not be laid down, because the missing bond would not allow a sufficiently closed surface to form.

In terms of price, the panels are very attractive and cost 11.80 EUR net (14.04 EUR gross) per square metre (when purchasing 100 square metres). For shipping, an average of 1.50 EUR gross per QM is added, resulting in a total price of approx. 15.50 EUR gross per QM. This is currently the cheapest reusable disk in our test and we are very curious to see how it will continue to perform in the coming months.

So far, the impression is definitely very good, and those who can’t lay their slush surfaces until spring, when the ground becomes drier again, should definitely take a look at the ArenaMat right now.